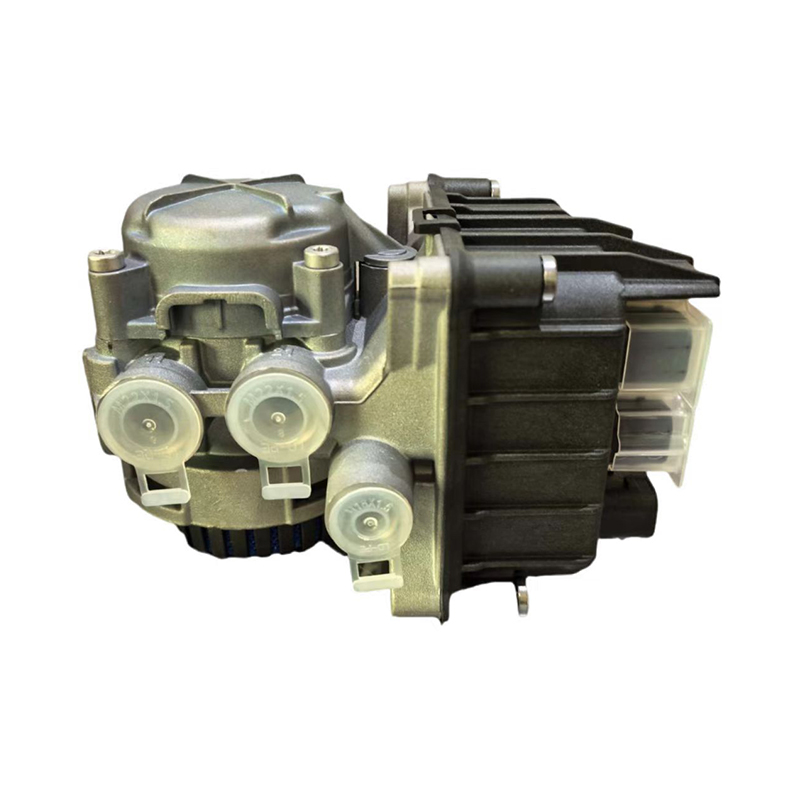

During severe cold seasons, the greatest threat to a commercial vehicle's pneumatic braking system is the freezing and blockage of the Brake Air Dryer. When the ambient temperature drops below freezing, if the internal Heater Element fails or the Desiccant Cartridge becomes saturated, condensation within the lines quickly turns to ice. This leads to a seized Purge Valve and complete air circuit failure, causing the vehicle to become stranded due to the inability to release the parking brakes. The following are professional emergency procedures and technical details for on-site recovery.

External Thermal Assistance: Targeting the Purge Valve and Body

When the compressor is running but the service tank pressure fails to rise, and no air exhaust is heard from the dryer, the Purge Valve inside the base is typically frozen shut.

Heat Source Application: Under field conditions, a portable heat gun or industrial hair dryer can be used to apply continuous heat to the dryer base, specifically around the exhaust port area. This thermal energy melts ice crystals surrounding the internal piston, restoring the movement of the valve flapper.

Avoid Open Flames: It is strictly forbidden to use open flames, such as torches, to heat the dryer base. The area surrounding the Brake Air Dryer contains plastic air lines, wiring harnesses, and internal rubber seals that are highly susceptible to irreversible damage or fire hazards from direct flame contact.

Mechanical Intervention: Vibration Clearance Method

If heating tools are unavailable, controlled mechanical vibration can sometimes provide a temporary solution.

Moderate Tapping: Use a rubber mallet or the handle of a wrench to gently tap around the aluminum base of the Brake Air Dryer. This vibration helps shatter thin ice layers at the Purge Valve seat. Combined with the pressure generated by the air compressor, this may force the blockage to clear.

Precision: Tapping must avoid the thin metal shell of the Desiccant Cartridge and the electrical sensor connectors to prevent shell rupture or electrical failure, which would result in more severe air leaks.

Pneumatic Emergency Treatment: Injection of Specialized De-icer

If the ice blockage is located deep within the unit, such as at the internal Check Valve, chemical intervention is required to lower the freezing point.

Signal Line Injection: Disconnect the intake line from the compressor to the dryer and inject a small amount of specialized Air Brake Antifreeze (typically isopropyl alcohol-based). Reconnect the line and start the engine; the compressed air will carry the antifreeze into the dryer to dissolve the ice.

Precaution: This method is for emergency rescue only. Excessive use of antifreeze degrades the lifespan of the media inside the Desiccant Cartridge. The cartridge must be replaced with a new unit as soon as possible following the emergency.

Bypass and Inspection: Troubleshooting the Control Circuit

Sometimes the freezing point is not in the main circuit but in the Unloader Line between the Governor and the dryer.

Clearing the Signal Line: Inspect the small-diameter tube connected to the dryer control port. If condensation freezes in this line, it may send a false unload signal to the dryer. Removing the line to clear water and ice before reconnecting often resolves the issue where the system fails to build pressure.

Heater Power Verification: Check the electrical plug at the bottom of the dryer for looseness. Use a multimeter to verify 24V/12V power supply to ensure the Heater Element is functioning during vehicle operation.

Preventative Drainage: Reservoir Maintenance

Once the Brake Air Dryer blockage is cleared, all vehicle air reservoirs must be manually drained immediately.

Eliminating Secondary Hazards: Even if the dryer is operational, residual moisture may still exist in the downstream system, such as relay valves or brake chambers. Open the manual drain valves at the bottom of the tanks until only dry air is exhausted to prevent further freeze-ups in the braking hardware.