Air dryers and air dryer filters are both vital components of compressed air systems. They each have different tasks. Although they overlap in function, their functions and working principles are significantly different. Understanding the difference between the two is crucial for users to correctly select and maintain compressed air systems.

Functions and Roles of Air Dryers

The main function of an air dryer is to ensure that the air in the system reaches an ideal dry state by removing moisture and humidity from the compressed air. After being processed by a compressor, compressed air usually contains a certain amount of moisture. If this moisture is not removed in time, it will cause corrosion and icing to the equipment, thereby affecting the stability and efficiency of the entire system.

Air dryers are generally divided into two types: refrigerated dryers and adsorption dryers. Refrigerated dryers condense the moisture in the air into liquid water by lowering the air temperature, and then discharge it through the drainage system; while adsorption dryers use adsorption materials (such as silica gel or molecular sieves) to adsorb moisture in the air to achieve the purpose of drying.

Functions and Roles of Air Dryer Filters

The air dryer filter is an important component inside the air dryer, responsible for further fine filtering of impurities and tiny particles in the air. The filter element mainly removes solid impurities, oil mist and tiny particles in the air through the filtering mechanism to ensure the clean air in the system. Although the air dryer itself has a certain moisture removal function, oil mist, fine particles and other substances in the air still exist and must be further cleaned by a high-efficiency filter element.

In practical applications, the working principle of the air dryer filter element usually relies on multi-layer filter materials, such as fiber, polyester and activated carbon, which can effectively remove oil mist and other impurities in the air. The replacement cycle of the filter element is usually related to the air quality and frequency of use. Timely replacement of the filter element can maintain the optimal operating state of the system.

Functional differences

Functions of air dryers:

Remove moisture: The core function of the air dryer is to remove moisture from the compressed air, prevent moisture from condensing or freezing in the system, and protect pipelines, valves and other key equipment.

Reduce the humidity of compressed air: By reducing the humidity of the air, the air dryer can effectively avoid the corrosion problem caused by moisture in the compressed air and extend the service life of the equipment.

Functions of air dryer filter element:

Filter impurities: The air dryer filter element mainly removes solid impurities, oil mist, dust and other pollutants in the air by physical filtration to ensure that clean and dry compressed air enters the system.

Fine filtration: The fine filtration mechanism of the filter element can ensure that tiny oil mist particles and water droplets in the air are effectively removed, thereby protecting subsequent equipment from contamination.

Structural differences

Structure of air dryer:

The air dryer consists of multiple core components, usually including cooling system, filtration system, drainage system and control system. Each part is designed to achieve the goal of air drying and can efficiently remove moisture from the air. The refrigerated air dryer has a built-in cooler to condense moisture by lowering the air temperature; the adsorption air dryer relies on adsorbents to absorb moisture in the air.

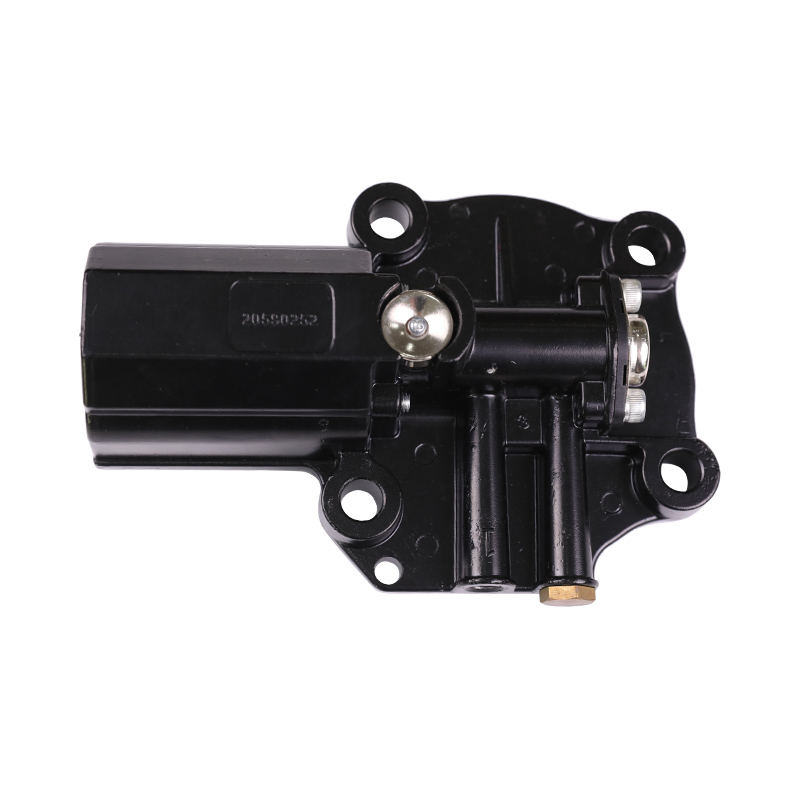

Structure of air dryer filter element:

The structure of the air dryer filter element is relatively simple, mainly consisting of filter material and shell. The filter material in the filter element may include synthetic fiber, metal mesh, activated carbon, etc., which can be selected according to different needs. The filter element is relatively easy to replace. Users can replace the filter element regularly according to usage to ensure the filtering effect.

Performance Differences

Performance of air dryers:

The performance indicators of air dryers mainly include drainage capacity, working pressure range, air flow handling capacity, etc. Air dryers with good performance can operate stably within a large working pressure and temperature range to ensure the effective removal of moisture in compressed air. Different types of air dryers have different performances, and the selection should be based on actual needs.

Performance of air dryer filter element:

The performance of air dryer filter element focuses on filtration accuracy and durability. A good filter element can effectively filter tiny impurities and oil mist, ensure that the air quality is not polluted, and avoid system failure. At the same time, the durability of the filter element directly affects the replacement cycle, and high-quality filter elements can maintain a high filtration efficiency for a long time.

Maintenance and replacement

Maintenance of air dryers:

Maintenance of air dryers includes regular inspection of drying effect, whether the drainage system is working properly, and cleaning of the cooling system. For adsorption air dryers, it is also necessary to regularly check the use of the adsorbent to ensure its drying effect. In case of failure, the condenser or adsorbent may need to be replaced.

Maintenance of air dryer filter:

The maintenance of the filter is relatively simple. Usually, you only need to check the filter effect regularly to determine whether it needs to be replaced. When the filter is excessively clogged or its performance is degraded, it must be replaced in time, otherwise it will affect the air quality and cause unstable system operation.