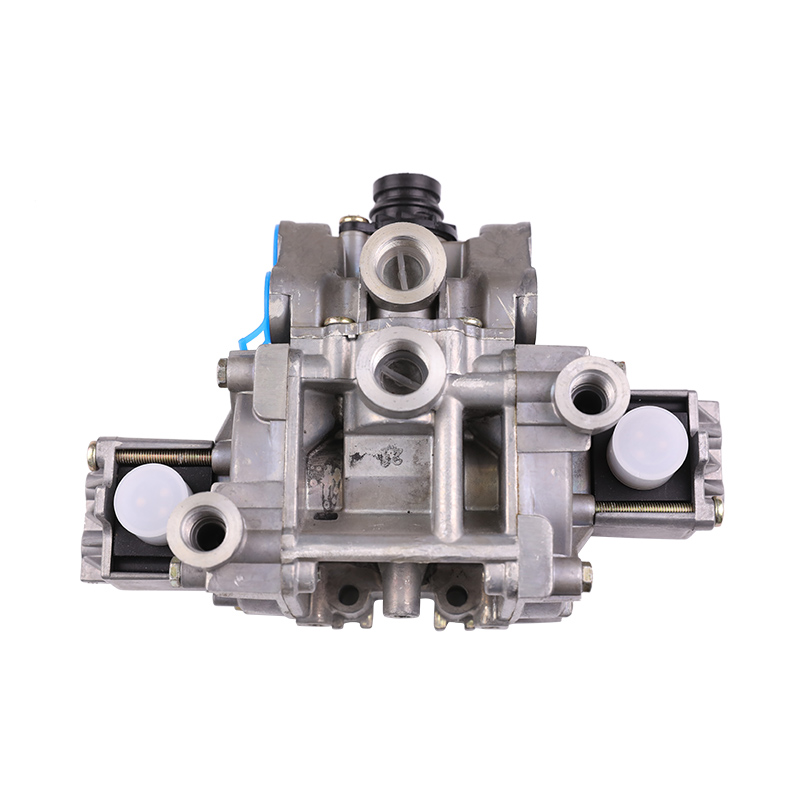

In the safety management system of commercial vehicles, the reliability of the Brake Foot Valve directly impacts the effectiveness of the Service Brake. Due to its complex operating environment and high frequency of use, establishing a scientific preventive maintenance plan is core to reducing accident risks and extending system life. This article explores professional recommendations for mandatory inspection milestones and key maintenance focus areas for the Brake Foot Valve.

Initial Break-in Inspection: 10,000 km to 20,000 km

Following the deployment of a new vehicle or the installation of a new Brake Foot Valve assembly, the initial break-in period is critical.

Within the first 10,000 to 20,000 km of operation, an initial visual and functional inspection should be performed. Focus specifically on whether Fittings have loosened due to vehicle vibration. Since the pneumatic circuit may contain residual fine impurities from manufacturing, the Exhaust Port must be checked for abnormal oil discharge or debris accumulation. The goal of this phase is to verify Installation quality and prevent early minor leaks from compromising long-term braking performance.

Routine Maintenance Cycle: Every 50,000 km or Quarterly

For the majority of long-haul trucks, 50,000 km represents a standard preventive maintenance milestone.

At this stage, the focus shifts to the dynamic response of the Brake Foot Valve. Technicians should test the Treadle stroke to ensure it is smooth and free from sticking or slow return issues. Crucially, this must be coordinated with an inspection of the Air Dryer desiccant cartridge. If the dryer fails, moisture entering the valve body will cause premature oxidation of the internal springs and pistons within the Brake Foot Valve.

Mandatory Deep Inspection Milestone: 150,000 km to 200,000 km

When a vehicle reaches between 150,000 km and 200,000 km, a deep technical evaluation or mandatory teardown inspection of the Brake Foot Valve is required. At this mileage, internal O-ring seals and Rubber Diaphragm components have endured millions of pressure cycles, entering the high-risk period for material fatigue.

Professional procedures at this stage include:

Internal Seal Testing: Using high-precision gauges to detect pressure balance between the primary and secondary circuits.

Lubrication Assessment: Checking if the grease on moving piston parts has dried or carbonized.

Sealing Surface Inspection: Examining the valve seats for scratches or pitting.

For vehicles operating in harsh environments—such as mining, high-salinity areas, or frequent stop-and-go urban delivery—this mandatory inspection should be moved forward to 100,000 km.

Adjustment Strategies for Extreme Environments

Mileage is not the sole metric; Operating Conditions have a decisive impact on maintenance intervals. In frigid regions, a Brake Foot Valve airtightness test is mandatory before winter to prevent frozen condensation from locking the valve core. Conversely, in hot and humid climates, the aging of rubber components accelerates, and it is recommended to increase Inspection frequency by over 20%. If the vehicle frequently travels on dusty roads, the integrity of the Rubber Boot should be added to the daily pre-trip inspection list.

Mandatory Replacement Cycle and Safety Life

While Repair Kits can address some wear, the aluminum alloy body of the Brake Foot Valve has a finite fatigue life. It is generally recommended to replace the Brake Foot Valve assembly entirely when the vehicle reaches 500,000 km or exceeds 5 years of service, regardless of current performance. Preventive replacement avoids sudden brake failure caused by metal fatigue or microscopic cracks in internal castings, aligning with the "replace rather than repair" safety philosophy of modern fleet management.

Critical Checkpoints During Mandatory Inspections

During any scheduled mileage inspection, the following three standard procedures must be executed:

Leakage Test

Under 80 psi to 100 psi of pressure, observe the Exhaust Port behavior during both application and release phases.

Mechanical Linkage Lubrication

Clean the pedal pivot pins and linkages, applying appropriate low-temperature grease.

Contamination Inspection

Check the compressed air entering the valve for excessive oil vapor, as surplus oil will degrade internal rubber components.

By implementing mandatory inspections at specific mileage nodes, operators significantly enhance Braking Safety and reduce fuel consumption and air compressor wear caused by system pressure loss.