Air dryer filters play a vital role in compressed air systems. Their main function is to remove moisture and impurities from the air and keep the compressed air dry. However, in low-temperature environments, especially in cold seasons, air dryer filters are prone to freezing, which not only affects the normal operation of the equipment, but may also cause system failures. To ensure the efficient operation of air dryer filters, effective measures need to be taken to prevent the occurrence of freezing problems.

Analysis of causes of freezing

The main reason for freezing of air dryer filters is that when compressed air passes through the dryer, water vapor condenses to form water droplets. If these water droplets are not discharged in time, they will freeze at low temperatures. Freezing can cause the passage of the filtration system to be blocked, thereby affecting the smooth flow of airflow, and may even cause equipment damage or reduced operating efficiency.

Key factors to prevent freezing

Reasonable air temperature control

The freezing problem of air dryer filters is closely related to air temperature. Under low temperature conditions, moisture in the air is more likely to condense to form ice. Therefore, keeping the system's intake temperature within a suitable range is the key to preventing freezing. Typically, the intake temperature of compressed air should be kept above 5°C, which can effectively reduce the probability of water vapor condensation.

Use cooling system to control temperature

To prevent low temperatures from causing ice to form on the air dryer filter, many air dryer systems are equipped with cooling systems. These systems can cool the compressed air to a suitable temperature, thereby reducing the condensation of water vapor in the air. If the intake temperature of the system is too high, the cooling system can reduce the temperature by cooling the air to avoid ice formation due to excessive temperature differences.

Timely drainage design

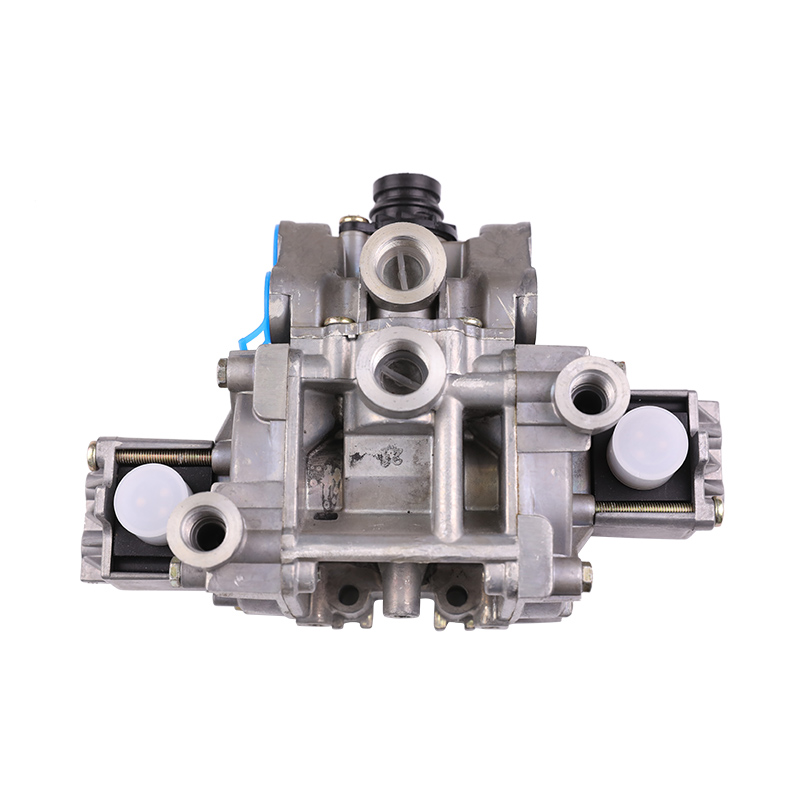

The design of the air dryer filter should have an efficient drainage function to drain water out of the system in time. When the compressed air passes through the dryer, the water condenses in the filter element to form water droplets. If these water droplets are not discharged in time, they are likely to freeze inside the filter element. Therefore, a reasonable drainage mechanism is the key to preventing ice formation. Many modern dryers are equipped with automatic drainage devices, which can automatically drain the accumulated water when the air passes through the filter element to avoid ice formation.

Choose the right type of dryer for the environment

Different types of air dryers are suitable for different working environments. If the ambient temperature is low, you should choose a refrigerated dryer or an adsorption dryer. These dryers have good drying performance under low temperature conditions and can effectively reduce the risk of freezing. Especially in areas with low temperatures, it is very important to choose the right type of dryer.

Regularly check and replace the filter element

After long-term use, the air dryer filter element may reduce the filtering effect due to water or oil pollution, increasing the risk of freezing. Therefore, regular inspection and replacement of the filter element is an effective measure to prevent freezing. After the dryer filter element has been used for a period of time, the filter element should be replaced in time according to the manufacturer's recommendations or usage conditions to ensure its filtering effect and drainage performance and prevent freezing.

Keep the system dry

Maintenance and maintenance of air compressors and related equipment are essential to prevent filter element freezing. Moisture in compressed air is the root cause of freezing, so it is very important to ensure the dryness of the entire system. You can reduce the moisture content in the air by regularly cleaning the compressor, checking the pipe connections, and installing a moisture separator to avoid the occurrence of freezing problems at the source.

Use low-temperature antifreeze additives

In extremely cold environments, you can consider using low-temperature antifreeze additives, which can lower the freezing point of moisture in the air and reduce the risk of freezing. However, when using antifreeze additives, you need to be careful to choose the type that is compatible with the equipment and follow the manufacturer's instructions to avoid adverse effects on the equipment.

Install a heater

In some extremely cold environments, the air dryer system may freeze due to low temperatures, causing the equipment to not work properly. Installing a heater is another effective way to prevent freezing. The heater can provide additional heat to the system to ensure that the air temperature is maintained in the appropriate range to prevent moisture from freezing.

Avoid over-compressing the air

Over-compressing the air will increase the humidity of the air, especially after the air is cooled, and excessive water vapor may cause freezing problems. Moderate air compression can effectively reduce the probability of water vapor condensation, thereby reducing the risk of freezing.

The importance of regular maintenance and inspection

The normal operation of the air dryer filter element is inseparable from regular maintenance and inspection. By regularly checking the working status of the system, potential problems can be discovered and solved in time. For example, by checking whether the drainage system is working properly and whether there is water accumulation in the filter element, the system can be prevented from malfunctioning due to freezing. Regularly cleaning the accumulated water in the air dryer, checking the integrity of the filter element, and ensuring the efficient operation of the air dryer are effective ways to ensure the prevention of freezing.