A Deep Dive into the Core of Truck Braking Systems: What Are Brake Chambers and Their Differences?

Introduction

Brake Chambers are essential executing components within the air brake systems of heavy commercial vehicles (such as trucks, buses, and trailers). Air brake systems are widely used due to their high reliability and powerful braking force, necessary for vehicles that carry heavy loads and operate for extended periods. The task of the Brake Chambers is critical: they function as an energy conversion station, efficiently and reliably transforming the compressed air pressure signal—initiated by the driver via the brake pedal (foot valve)—into the mechanical thrust required to actuate the brake mechanisms (such as S-cams or disc brake calipers).

Without Brake Chambers, the immense energy within the air pressure system could not be converted into the actual braking force necessary to decelerate or stop the vehicle. Therefore, the performance, reliability, and correct maintenance of Brake Chambers are directly related to the vehicle's driving safety and operational efficiency.

Preliminary Understanding of Spring Brake Chambers

With the continuous improvement of automotive safety regulations and the increasing demand for parking and emergency braking in commercial vehicles, a special type of Brake Chambers emerged: the Spring Brake Chambers (also often referred to as "dual diaphragm chambers" or "energy storage chambers").

Unlike standard Brake Chambers, which only provide service braking, Spring Brake Chambers ingeniously integrate a powerful, pre-compressed mechanical spring. This design grants them a dual function:

- Service Braking (Normal Braking): The front chamber of the air chamber handles the daily braking function, working on a principle similar to the standard air chamber.

- Parking/Emergency Braking: The rear chamber utilizes the mechanical force of the spring. When air pressure is normal, the spring is held compressed by the air pressure and remains inactive; however, when the driver parks the vehicle, or if system air pressure drops to a dangerous level due to a leak or failure, the spring releases its stored energy automatically to apply braking force, thus providing parking and fail-safe emergency braking.

This Fail-Safe design mechanism makes Spring Brake Chambers indispensable safety components on the rear axles of modern heavy commercial vehicles and on trailers.

For an initial comparison of these two fundamental types of Brake Chambers, please refer to the table below:

| Feature | Standard Brake Chamber (Standard/Service Chamber) | Spring Brake Chamber (Dual/Spring Chamber) |

|---|---|---|

| Primary Function | Provides only Service Braking | Provides Service, Parking, and Emergency Braking |

| Structure Simplicity | Simple (single diaphragm, single chamber) | Complex (dual diaphragm, dual chamber, contains high-pressure spring) |

| Braking Principle | Air pressure driven | Air pressure driven (Service); Mechanical spring driven (Parking/Emergency) |

| Safety Mechanism | Relies on air pressure; braking capability is lost if air pressure fails | Fail-Safe design; automatically locks wheels upon air pressure loss |

| Typical Application Location | Primarily used on front axles | Primarily used on rear axles or trailer axles |

What is a Brake Chamber and What are Its Fundamentals?

Definition

A standard Brake Chamber (also known as a Service Brake Chamber) is an executing device in the air brake system that converts energy forms. It is a sealed chamber designed to receive compressed air pressure from the relay valve or brake valve and efficiently convert this pneumatic energy into usable straight-line mechanical force. This mechanical thrust (usually outputted by a push rod) is the primary power source for applying the wheel brake mechanisms, whether it be the S-cam for drum brakes or the caliper for disc brakes.

Primary Function

The core function of the Brake Chamber is to convert compressed air pressure into mechanical force to apply the brakes. This conversion strictly follows a variation of Pascal's Principle:

Force (F) = Pressure (P) * Effective Area (A)

- Pressure (P): The compressed air pressure, controlled by the brake valve and supplied by the compressor and reservoir, typically measured in pounds per square inch (psi) or Pascals (Pa).

- Effective Area (A): The effective working area of the diaphragm inside the Brake Chamber, typically measured in square inches.

- Thrust (F): The mechanical force outputted by the push rod, which acts directly on the slack adjuster and is the source of the braking force applied to the wheels.

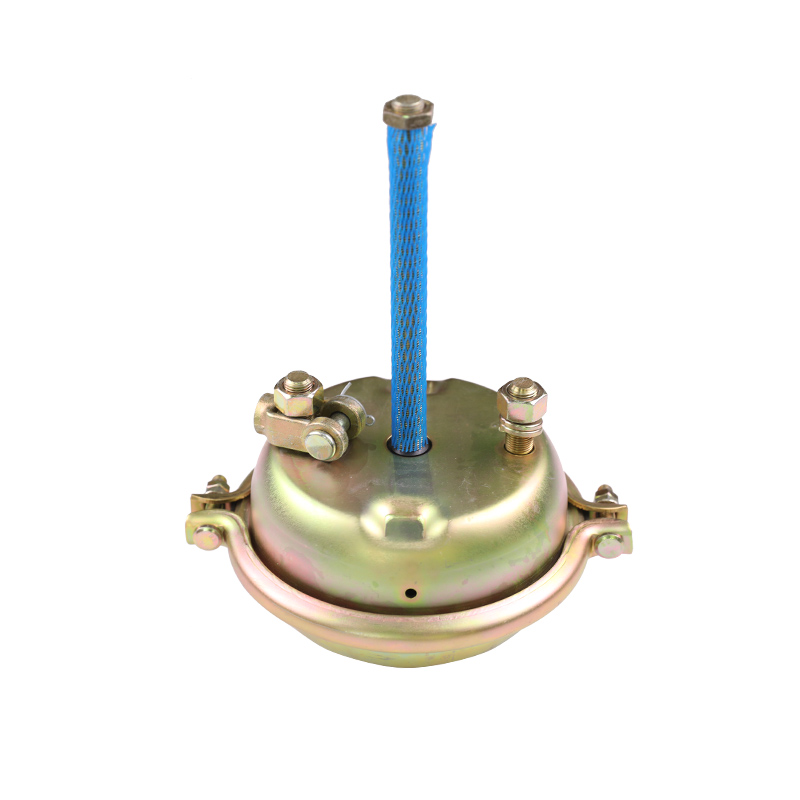

Basic Components

The standard Brake Chamber has a simple and reliable structure, consisting mainly of the following three key components:

| Component | Description | Primary Function |

|---|---|---|

| Housing | Composed of two metal or composite material half-shells, forming an airtight chamber. | Provides structural support, protects internal components, and defines the diaphragm's working space. |

| Diaphragm | A flexible, high-strength, airtight piece of material (usually synthetic rubber or reinforced fibre), located inside the chamber. | Withstands compressed air pressure and transmits the pressure to the push rod, accomplishing energy conversion. |

| Push Rod | A metal rod connected to the centre of the diaphragm and extending out of the air chamber. | Outputs the straight-line mechanical force generated on the diaphragm to the external slack adjuster. |

| Return Spring | A small helical spring located near the diaphragm and push rod. | Ensures the diaphragm and push rod quickly return to the initial, non-braking position after the brake is released (air is exhausted). |

Working Principle

The standard Brake Chamber is used only for service braking. Its operation can be divided into the following stages:

- Brake Request (Applying): The driver depresses the brake pedal, and compressed air is directed into the Brake Chamber from the reservoir, passing through the brake valve and relay valve. The compressed air acts on the diaphragm. According to the F=P * A principle, the diaphragm begins to move. The diaphragm pushes the central push rod outwards. The end of the push rod connects to and rotates the slack adjuster.

- Brake Execution (Braking): The rotating slack adjuster drives the S-cam in drum brakes to push the brake shoes against the drum; or it drives the caliper piston in disc brakes to press the brake pads against the disc. The magnitude of the braking force is directly proportional to the air pressure inside the chamber.

- Brake Release (Releasing): The driver releases the brake pedal, the brake valve cuts off the air supply and opens the exhaust port. The compressed air inside the Brake Chamber is rapidly exhausted, and the pressure inside the chamber drops. The Return Spring pulls the diaphragm and push rod back to their initial positions, the slack adjuster and S-cam reset, and the brake is released.

Technical Specifications Comparison: Size Nomenclature

The size of Brake Chambers is typically designated using a standardised Type number, which directly corresponds to the effective working area of the air chamber diaphragm in square inches . This is the key parameter for measuring the maximum thrust an air chamber can generate:

| Type | Effective Area (in$^2$) | Typical Application | Note |

|---|---|---|---|

| Type 9 | 9 | Light trucks/Trailer auxiliary braking | Rarely used for heavy main braking |

| Type 12 | 12 | Light commercial vehicles or some front axles | Lower thrust requirement |

| Type 20 | 20 | Medium truck front axles | Common specification |

| Type 24 | 24 | Heavy truck front axles/Light rear axles | Frequent specification |

| Type 30 | 30 | Heavy truck front/rear axles (or as the service chamber of a spring chamber) | Most common industry size, highest thrust for a standard chamber |

| Type 36 | 36 | Special heavy-load applications | Requires maximum thrust |

What is a Spring Brake Chamber and What is Its Dual Role?

Definition

The Spring Brake Chamber is an advanced and highly safe Brake Chamber design, often known in the industry as a Dual Chamber or Energy Storage Chamber. It does more than just perform service braking; crucially, it integrates essential parking and emergency braking functions. Structurally, it essentially combines a standard service Brake Chamber with an independent spring energy storage chamber within a single housing.

Dual Function

The complex design of the Spring Brake Chamber gives it a unique and irreplaceable dual role in commercial vehicle braking systems:

- Service Braking (Normal Braking): The front chamber of the air chamber handles the daily braking function, working on a principle similar to the standard air chamber.

- Parking/Emergency Braking: The rear chamber utilizes the mechanical force of the spring. When air pressure is normal, the spring is held compressed by the air pressure and remains inactive; however, when the driver parks the vehicle, or if system air pressure drops to a dangerous level due to a leak or failure, the spring releases its stored energy automatically to apply braking force, thus providing parking and fail-safe emergency braking.

This Fail-Safe design mechanism makes Spring Brake Chambers indispensable safety components on the rear axles of modern heavy commercial vehicles and on trailers.

Key Components

Unlike the standard single-chamber Brake Chamber, the complexity of the Spring Brake Chamber lies in its two independent chambers and the high-energy spring:

| Component | Location and Structure | Primary Function |

|---|---|---|

| Service Brake Chamber | Located in the front of the air chamber, connected to the external air line. | Receives air pressure from the foot valve to provide daily service braking force. Functionally identical to a standard Brake Chamber. |

| Spring Brake Chamber | Located in the rear of the air chamber, it is a sealed energy storage space. | Area containing and controlling the high-pressure parking spring. |

| Powerful Parking Spring (Spring) | Located inside the spring brake chamber, it is highly pre-compressed. | The mechanical energy storage element, used to provide parking and emergency braking force when air pressure is released or insufficient. |

| Spring Piston | Located inside the spring brake chamber, used for sealing and transmitting air pressure. | Withstands parking air pressure to keep the spring compressed (released) during driving. |

| Manual Release Bolt (Caging Bolt/Manual Release) | Located at the rear end of the air chamber, used for manual operation. | Used to safely compress the parking spring manually (releasing the brake) when there is no air pressure or when a locked vehicle needs to be moved. |

Working Principle

1. Service Braking Principle

This part operates identically to a standard Brake Chamber and relies on the Service Brake Chamber (front chamber). Compressed air enters the front chamber, acts on the diaphragm, and pushes the central push rod to apply the brake. Crucially, the air pressure in the Spring Brake Chamber (parking release pressure) remains high, holding the powerful parking spring compressed and inactive.

2. Parking/Emergency Braking Principle

This part relies on the Spring Brake Chamber (rear chamber):

- Brake Release (Driving Status): High-pressure air (typically 100-120 psi) is continuously fed into the Spring Brake Chamber. This air pressure acts on the spring piston, compressing the spring and keeping it "caged."

- Brake Application (Parking or Emergency Status):

- Parking: The driver manually exhausts all compressed air from the Spring Brake Chamber.

- Emergency: System air pressure drops below a critical threshold (typically around 45 psi) due to a failure.

Once the air pressure is removed or drops, the tremendous pre-compressed force of the parking spring overcomes the remaining air pressure and pushes the push rod outwards, applying mechanical force to lock the wheels. This is a completely independent mechanical backup.

Key Parameter Comparison: Spring Force and Critical Pressure

The performance of the Spring Brake Chamber depends not only on the diaphragm area (Type 30 etc.) but also on the parameters of its internal spring:

| Parameter Category | Description | Typical Numerical Range |

|---|---|---|

| Parking Spring Force | The maximum thrust the spring can generate when fully released (excluding friction loss). | 1500 lbf to 3500 lbf (depending on the air chamber model) |

| Release Pressure | The minimum air pressure required to keep the spring fully compressed. | Typically above 90 psi |

| Critical Braking Pressure | The air pressure threshold at which the system automatically triggers the spring brake (automatic lockup). | Typically between 40 psi and 45 psi |

| Chamber Type Combination | The air chamber is usually denoted by the Type numbers of its two chambers (e.g., Type 30/30). | 24/30 (Front chamber Type 24, Rear chamber Type 30), 30/30, etc. |

What are the Key Differences Between Brake Chambers and Spring Brake Chambers?

Although both standard Brake Chambers (Service Chambers) and Spring Brake Chambers (Dual Chambers) serve the air brake system, they have fundamental differences in design philosophy and function. These distinctions determine their specific roles and applications within a vehicle's braking system.

Functionality Differences

| Feature | Standard Brake Chamber (Service Chamber) | Spring Brake Chamber (Dual Chamber) | Significance |

|---|---|---|---|

| Primary Function | Service Brakes only | Service Brakes, Parking Brakes, and Emergency Brakes | The spring chamber possesses the safety backup function required by regulations. |

| Parking Capability | None (cannot provide parking braking force) | Yes (provides mechanical locking force by releasing the spring) | Parking braking must be supplemented by other means (e.g., driveline brakes or hydraulic systems) if a spring chamber is not used. |

| Emergency Capability | None (braking is lost if air pressure fails) | Yes (automatically triggers when air pressure drops below a critical level) | Ensures the vehicle can be safely stopped in the event of an air line failure or system leak. |

Component Structure Differences

| Feature | Standard Brake Chamber (Service Chamber) | Spring Brake Chamber (Dual Chamber) | Structural Comparison |

|---|---|---|---|

| Number of Chambers | Single Chamber (one service brake chamber) | Dual Chamber (one service chamber + one spring chamber) | The spring chamber is significantly more complex, increasing size and maintenance difficulty. |

| Core Energy Storage | Return Spring (lightweight, only for push rod return) | Powerful Parking Spring (heavy-duty, high compression ratio, stores immense mechanical energy) | The parking spring is the most crucial component distinguishing the two. |

| Push Rod | Only one push rod, used for service braking. | One push rod, but driven jointly by the service chamber diaphragm and the spring piston. | The push rod linkage in a spring chamber is more complex. |

| Manual Operation Part | None | Manual Release Bolt (Caging Bolt) | Used to manually release the spring brake when there is no air pressure, a unique safety operation component of the spring chamber. |

Safety Considerations

| Feature | Standard Brake Chamber (Service Chamber) | Spring Brake Chamber (Dual Chamber) | Safety Evaluation |

|---|---|---|---|

| Braking Mechanism | Relies on air pressure to apply and maintain braking. | Fail-Safe mechanism. | Spring chambers are safer, because they provide a mechanical backup in case of system failure. |

| Air Pressure vs. Braking Force | Brakes when air pressure is high; no braking when air pressure is low. | Releases (disengages brake) when air pressure is high; applies brake when air pressure is low. | The spring chamber's principle is the opposite of the standard chamber, ensuring a constant source of braking force. |

| Parking Safety | Requires continuous air pressure or relies on mechanical locks for parking, risk is higher. | Parking force is provided by the mechanical spring; it does not rely on the air source, resulting in extremely high parking safety. |

Application Location Differences

| Feature | Standard Brake Chamber (Service Chamber) | Spring Brake Chamber (Dual Chamber) | Application Principle |

|---|---|---|---|

| Typical Application | Any axle requiring air pressure braking force. | Axles that must have parking brake functionality. | Parking brakes must be applied to axles capable of effectively locking the vehicle. |

| Common Axle Position | Front Axles | Rear Axles and Trailer Axles | Avoiding the use of spring brakes on front wheels prevents accidental front wheel lock-up and loss of control during emergency braking. |

| Trailer Braking | Insufficient to meet trailer braking requirements alone. | Standard configuration for trailer air brake systems. | Trailers must automatically brake and lock up when separated from the tractor or if the air supply line is unexpectedly broken. |

Weight and Size Differences

| Feature | Standard Brake Chamber (Type 30 Example) | Spring Brake Chamber (Type 30/30 Example) | Impact Factor |

|---|---|---|---|

| Volume/Length | Shorter and smaller | Significantly longer | Additional space required to house the parking spring and the second chamber. |

| Weight | Lighter | Significantly heavier | The powerful high-strength spring, heavy piston, and extra housing increase overall weight. |

| Cost | Lower | Higher | Complex structure, the manufacture of high-pressure springs, and strict sealing requirements drive up the cost. |

What is the Performance Analysis of Brake Chambers Systems?

A performance analysis of the two main types of Brake Chambers helps in understanding their respective scopes of application and limitations. Performance assessment is based not only on braking force but also on multiple dimensions including structural complexity, cost, weight, and safety.

Advantages and Disadvantages of Standard Brake Chamber

The standard Brake Chamber (Service Chamber) is designed for the efficient and simple execution of the service braking task.

| Evaluation Dimension | Advantages | Disadvantages |

|---|---|---|

| Structure and Weight | Simpler and Lighter: Single-chamber design, fewer components, lighter weight, which helps reduce the vehicle's curb weight and improves fuel efficiency. | No Parking Function: Must rely on other parking mechanisms (e.g., driveline lock) or use Spring Brake Chambers to supplement parking braking. |

| Cost and Maintenance | Lower Initial Cost: Simple structure, lower manufacturing cost, procurement and replacement costs are generally lower than dual-chamber air chambers. | Safety Limitation: Braking force generation and sustainment rely entirely on compressed air. A severe air system leak will result in a complete loss of braking force. |

| Response Speed | Fast Braking Response: Smaller chamber volume allows for faster inflation and exhaustion, contributing to more sensitive and timely service braking. | Lack of Safety Backup: Does not have the Fail-Safe mechanism required by regulations and cannot serve as an emergency braking device. |

| Application Restrictions | Limited Applicability: Cannot independently meet the regulatory requirements for parking and emergency braking in heavy vehicles. | Unable to provide mechanical braking. |

Advantages and Disadvantages of Spring Brake Chamber

The Spring Brake Chamber (Dual Chamber) is designed to provide critical safety and parking functions alongside service braking.

| Evaluation Dimension | Advantages | Disadvantages |

|---|---|---|

| Safety | Integrated Parking and Emergency Braking: Core advantage is its Fail-Safe design, the spring provides powerful mechanical force to lock the vehicle even with a complete loss of air pressure. | More Complex and Heavier: Dual-chamber structure and high-strength spring make the air chamber larger and significantly heavier, impacting load capacity. |

| Reg. Compliance | Full Compliance: Can meet the mandatory requirements for parking and emergency braking force for heavy commercial vehicles in most countries and regions. | Higher Initial Cost: Due to the complex internal structure, high-strength materials, and precise manufacturing requirements, the procurement cost is higher. |

| Braking Force Assurance | Mechanical Spring Force: Parking force is stable and independent of air pressure fluctuations, ensuring safety during long-term parking. | Increased Maintenance Difficulty: Complex structure, containing a high-pressure spring; maintenance and manual release operations (Caging) must strictly adhere to safety procedures to avoid the risk of accidental spring release. |

| Performance Consideration | Dual Function Integration: Solves both service and parking braking problems within one component, simplifying system layout. | Slightly Slower Response: The larger spring chamber volume means slightly longer inflation and exhaustion times compared to standard air chambers, which can subtly affect braking response time. |

Performance Parameter Comparison Summary

To visually compare the performance differences between the two Brake Chambers, the following key parameters should be considered:

| Parameter | Standard Brake Chamber (Service Chamber) | Spring Brake Chamber (Dual Chamber) |

|---|---|---|

| Core Safety Mechanism | Air pressure driven | Mechanical spring driven (Fail-Safe) |

| Average Weight Comparison (Approximate Type 30 / 30/30) | Approx. 10 lbs to 15 lbs | Approx. 20 lbs to 35 lbs |

| Source of Parking Force | None (system external) | Powerful pre-compressed mechanical spring |

| System Complexity | Low | High |

| Typical Application Cost | Base cost | Base cost + Parking safety premium |

What Are the Regulations and Technical Standards Governing Brake Chambers?

As a critical component in heavy commercial vehicle safety systems, the design, performance, and reliability of Brake Chambers are subject to strict international and regional regulatory constraints. These standards ensure that vehicles can stop and park safely under all operating conditions.

North American DOT (FMVSS) Regulations

In the United States and Canada, the core standard for commercial vehicle braking systems is the Federal Motor Vehicle Safety Standard (FMVSS), with FMVSS 121 (for air brake systems) setting mandatory requirements for Brake Chambers:

| Regulatory Requirement | FMVSS 121 (North America) | Implementation via Brake Chambers |

|---|---|---|

| Minimum Parking Braking Force | The vehicle must be able to park on a 20% gradient, or the parking braking force must meet a specific percentage of the GVW at maximum load. | Mandates the use of Spring Brake Chambers on drive axles to provide continuous mechanical parking force via high-strength springs. |

| Emergency Braking Function | Vehicle must maintain a certain level of braking effectiveness in the event of a single-circuit brake system failure or air pressure loss. | The Fail-Safe design of Spring Brake Chambers (automatic braking upon air pressure loss) is the primary means of meeting this requirement. |

| Braking Time Requirement | Specifies an upper limit for the time delay from the driver applying the brake until the push rod begins to move. | Requires that the inflation and exhaustion speed of Brake Chambers meet rapid response requirements, especially with relay valves. |

International ECE Regulations (R13)

In Europe and many countries following UNECE standards, Regulation R13 also imposes strict requirements on Brake Chambers:

- Parking Brake: R13 requires the parking brake system to operate independently and use an energy storage element (like a spring) to maintain braking force.

- Emergency Braking: Specifies the minimum deceleration required when the brake system fails, heavily relying on the emergency release capability of Spring Brake Chambers.

- Performance Certification: Manufacturers must obtain Type Approval for Brake Chambers, certifying compliance with R13 annexes regarding durability, air tightness, and thrust output.

Size and Interface Standards

To ensure interchangeability and maintenance ease, the size and connecting interfaces of Brake Chambers follow highly standardized industry norms:

| Technical Parameter | Standard Description | Significance |

|---|---|---|

| Type Number (e.g., 30, 24) | Represents the effective area of the Brake Chamber diaphragm in square inches . | This is the core parameter determining the chamber's theoretical maximum thrust (F = P * A). |

| Chamber Combination Naming | Spring Brake Chambers use a dual number (e.g., Type 30/30), where the first number is the service chamber area and the second is the parking chamber area. | Allows technicians to quickly identify the air chamber's function and thrust output capability. |

| Push Rod Thread and Length | The size (e.g., M16 x 1.5) and length of the thread at the end of the push rod are standardised. | Ensures the Brake Chamber can be accurately connected to the slack adjuster. |

| Mounting Flange | The air chamber flange and mounting hole positions (e.g., bolt center distance and diameter) are standardised. | Ensures that Brake Chambers from different manufacturers can be interchanged without modifying the vehicle's chassis structure. |

Technical Performance Standards

Brake Chambers must meet strict performance and durability standards:

- Durability Testing: Must undergo hundreds of thousands of braking cycles, ensuring the diaphragm and spring do not experience fatigue or leakage.

- Air Tightness Requirements: Specifies the maximum allowed air leakage rate at maximum operating pressure, ensuring efficient system operation.

- Thrust Consistency: Requires the Brake Chamber's thrust output to remain stable and accurate within the specified air pressure and push rod stroke range.

What Are the Maintenance and Inspection Procedures for Brake Chambers?

Brake Chambers are high-pressure, high-frequency motion components, subject to harsh environments. Regular inspection and maintenance are vital for their safe operation, focusing on air tightness, effective thrust output, and mechanical integrity.

Routine Inspection of Brake Chambers

All types of Brake Chambers should undergo the following routine visual inspections:

- Housing Integrity: Check for dents, cracks, or severe corrosion.

- Air Line Connections: Check that the hoses and fittings are secure and free from wear or looseness.

- Mounting Flange: Ensure the air chamber mounting bolts are tight.

- Push Rod Condition: Check the push rod surface for cleanliness, smoothness, and signs of bending or corrosion.

Measuring and Adjusting Push Rod Stroke

Push rod stroke is the most critical parameter for assessing the working condition of Brake Chambers and directly affects braking performance:

| Condition | Description | Safety Hazard |

|---|---|---|

| Effective Stroke | The distance the Brake Chamber push rod travels from its resting position until the brake shoe/pad contacts the brake drum/disc. | Excessive slack in the brake adjuster or large brake clearance, causing the stroke to exceed the normal range. |

| Maximum Limit Stroke | The maximum safe stroke specified by regulations and manufacturers; exceeding this value is considered out-of-adjustment. | Severe loss of braking force, brake lag, or even complete brake failure. |

| Measurement Method | Measure the difference in the exposed length of the push rod after the brake is released and after the brake is fully applied. | Must be checked regularly, especially if the automatic slack adjuster fails. |

Common Issues with Standard Brake Chambers (Service Chambers)

| Common Issue | Possible Cause | Troubleshooting |

|---|---|---|

| External Air Leak | Loose air line fitting, aged or damaged O-ring, cracked air chamber housing. | Locate the leak point by applying soapy water or listening, tighten the fitting, or replace the air chamber. |

| Insufficient Braking Thrust | Damaged diaphragm (ruptured or perforated) leading to loss of air tightness. | Replace the entire Brake Chamber (diaphragms are typically not replaceable separately). |

| Stuck/Slow Push Rod Return | Fatigue of the internal return spring or corrosion/seizing of the push rod within the guide sleeve. | Inspect and clean the push rod, replace the air chamber if necessary. |

Common Issues with Spring Brake Chambers (Dual Chambers)

Spring Brake Chambers have more potential failure points, and maintenance requires higher safety standards:

| Common Issue | Possible Cause | Troubleshooting |

|---|---|---|

| Internal Air Leak (Spring Chamber) | Aged/damaged spring piston seal, leading to loss of parking air pressure. | Causes the parking spring to accidentally apply the brake; requires air chamber replacement. |

| Spring Fatigue | The air chamber has exceeded its service life or has been exposed to high temperatures. | Leads to reduced parking/emergency braking force; requires air chamber replacement. |

| Stuck Push Rod or Spring Piston | Severe internal corrosion or dirt accumulation. | Impairs both service and parking functions; must be replaced. |

| Seized Manual Release Bolt | Unused for extended periods, thread corrosion, or over-tightening. | Hampers the ability to move the locked vehicle in an emergency; requires cleaning, lubrication, or replacement. |

Importance of Regular Inspection and Maintenance

- Safety Assurance: Ensures Brake Chambers are always in optimal working condition.

- Regulatory Compliance: Ensures compliance with regulations (FMVSS 121 or ECE R13) and avoids fines.

- Extending Lifespan: Timely detection of issues prevents failure from escalating.

⚠️ Safety Warning: When maintaining Spring Brake Chambers, always ensure the system air pressure is safely exhausted and strictly follow the manufacturer's instructions using the correct tools (like the caging bolt) to prevent the extreme danger of the spring unexpectedly releasing.

What Are the Considerations for Choosing the Right Brake Chamber?

Selecting the correct type and size of Brake Chamber is a critical step in ensuring the performance and safety of a vehicle's braking system. The selection process must integrate factors such as the vehicle's purpose, weight, axle load distribution, and mandatory legal regulations.

Key Consideration Factors

| Consideration Factor | Impact Area | Selection Priority |

|---|---|---|

| Vehicle Type and Application | Determines whether integrated parking function is needed (e.g., heavy trucks, buses, trailers vs. light-duty equipment). | High |

| Legal and Regulatory Requirements | Mandates the use of Spring Brake Chambers to comply with emergency and parking brake regulations (e.g., FMVSS 121). | Highest |

| Axle Load Distribution (Axle Load) | Determines the required Brake Chamber size (Type number) to ensure sufficient thrust matches the required wheel braking torque. | High |

| Budget and Maintenance Cost | Impacts initial investment and long-term repair expenses. | Medium |

| Installation Space Constraints | Spring Brake Chambers are longer than standard air chambers and may be restricted by chassis installation space. | Medium |

When to Use a Standard Brake Chamber

Standard Brake Chamber (Service Chamber) is typically suitable for:

- Non-Driving Front Axles: Used in most heavy vehicles to provide service braking while maintaining steering control during emergencies.

- Cases Without Need for Independent Parking Brake: If parking is satisfied by another independent system.

- Pursuing Lightweighting and Space Optimization: Where weight and space are critical, and parking function is guaranteed elsewhere.

When to Use a Spring Brake Chamber

Spring Brake Chamber (Dual Chamber) is mandatory and standard for:

- Compliance with Parking/Emergency Brake Regulations: Required on drive axles and all trailer axles under FMVSS 121 or ECE R13.

- Rear Axles or Drive Axles: Most common application to provide effective parking lock-up and safety backup.

- Trailer Braking: Required on all air-braked trailers to ensure automatic braking when separated or when the air supply line is broken.

Selection Parameter Comparison: Size and Thrust

The most crucial step in selection is determining the correct size (Type number) based on thrust requirements:

| Chamber Type | Typical Type | Service Chamber Area (in$^2$) | Theoretical Max Thrust at 100 psi (lbf) | Application Tendency |

|---|---|---|---|---|

| Standard Chamber | Type 20 | 20 | 2000 | Medium truck front axles |

| Standard Chamber | Type 30 | 30 | 3000 | Heavy truck front axles |

| Spring Chamber | Type 24/30 | 24 (Service) / 30 (Parking) | 2400 (Service) / 3000 (Parking) | Heavy truck rear axles (drive axles) |

| Spring Chamber | Type 30/30 | 30 (Service) / 30 (Parking) | 3000 (Service) / 3000 (Parking) | Heavy-haul trucks or trailer axles requiring higher parking force |

Selection Principle: Thrust F must be sufficient to provide the required braking torque and meet regulatory deceleration requirements. Consult vehicle manufacturer specifications to ensure proper matching.

Frequently Asked Questions: What Are the Common Questions Regarding Brake Chambers?

This section addresses common questions about the operation, maintenance, and troubleshooting of Brake Chambers, especially Spring Brake Chambers.

Air Pressure and Braking Functionality

Q: Why do my truck brakes automatically apply when the air pressure drops below 60 psi?

A: This is the emergency braking function of the Spring Brake Chamber. Regulations mandate automatic brake application when system air pressure drops to the critical braking pressure, typically 40 psi to 45 psi. The 60 psi is often the system's warning trigger, indicating pressure is nearing the danger zone.

Q: What is a "Type 30" Brake Chamber, and how do I calculate its thrust?

A: "Type 30" indicates the chamber's effective working area is 30 square inches.

Thrust Calculation: Force (F) = Pressure (P) * Effective Area (A)

| Chamber Type | Effective Area (in$^2$) | Theoretical Thrust (lbf) |

|---|---|---|

| Type 20 | 20 | 2000 |

| Type 24 | 24 | 2400 |

| Type 30 | 30 | 3000 |

Maintenance and Safety Operation

Q: How do I manually release (Cage) a Spring Brake Chamber?

A: Manual release is used when there is no air pressure to safely compress the parking spring (releasing the brake) for towing or repair. Steps include securing the vehicle, locating the manual release bolt (Caging Bolt) at the rear of the chamber, installing the appropriate tool, and forcefully tightening the nut to mechanically compress the spring.

⚠️ Safety Warning: Always use the correct procedure and tools as this involves a high-energy spring.

Q: What is the danger of an over-long push rod stroke (Out-of-Adjustment)?

A: An over-long stroke means the push rod has travelled too far. This causes: severe loss of braking force (due to reduced effective area), increased brake lag, and the potential for complete brake failure if the stroke exceeds its safe limit.

Structure and Design

Q: What is the difference between Diaphragm Type and Piston Type Brake Chambers?

A: The difference lies in the sealing element used to convert air pressure into force:

| Feature | Diaphragm Type Chamber | Piston Type Chamber |

|---|---|---|

| Sealing Element | Flexible diaphragm (usually rubber/synthetic material) | Rigid piston, equipped with sealing rings (O-rings) |

| Travel Distance | Shorter stroke limitations. | Longer travel distance capability. |

| Application | Most common type for service chambers. | Certain heavy-duty or non-standard applications, and the parking chamber of some Spring Chambers. |